Technical information

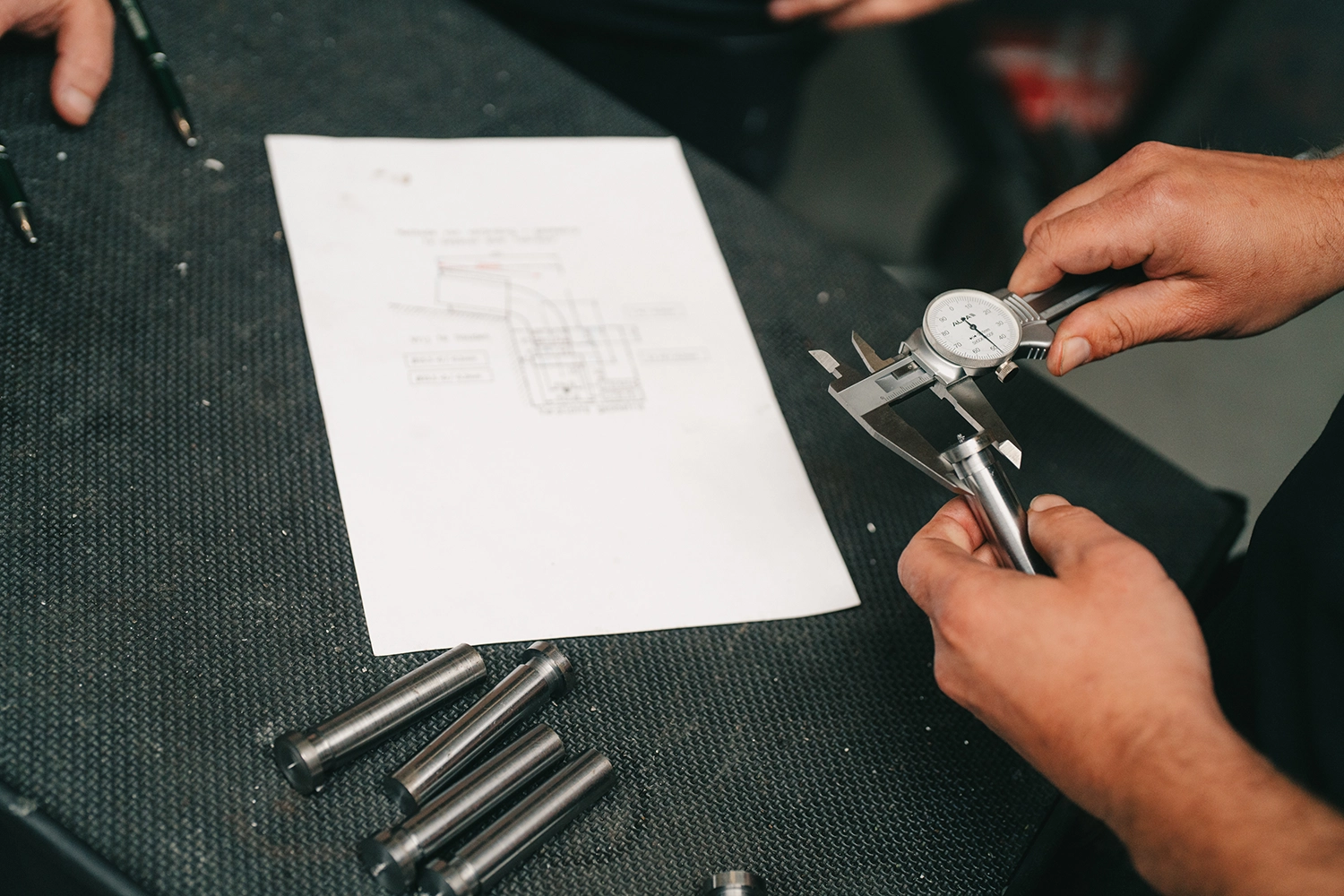

For the production of screw thread, at Merofix we use the thread rolling system, a method of chipless cold forming. Unlike cut thread, where material is removed, rolled thread provides a stronger, more accurate and durable connection.

In wire rolling, a metal rod of the correct diameter is deformed under high deformed. Instead of cutting out threads, the material is pressed into the correct shape, pushing it outwards. This increases the diameter without loss of material. The screw thread becomes a lot stronger.

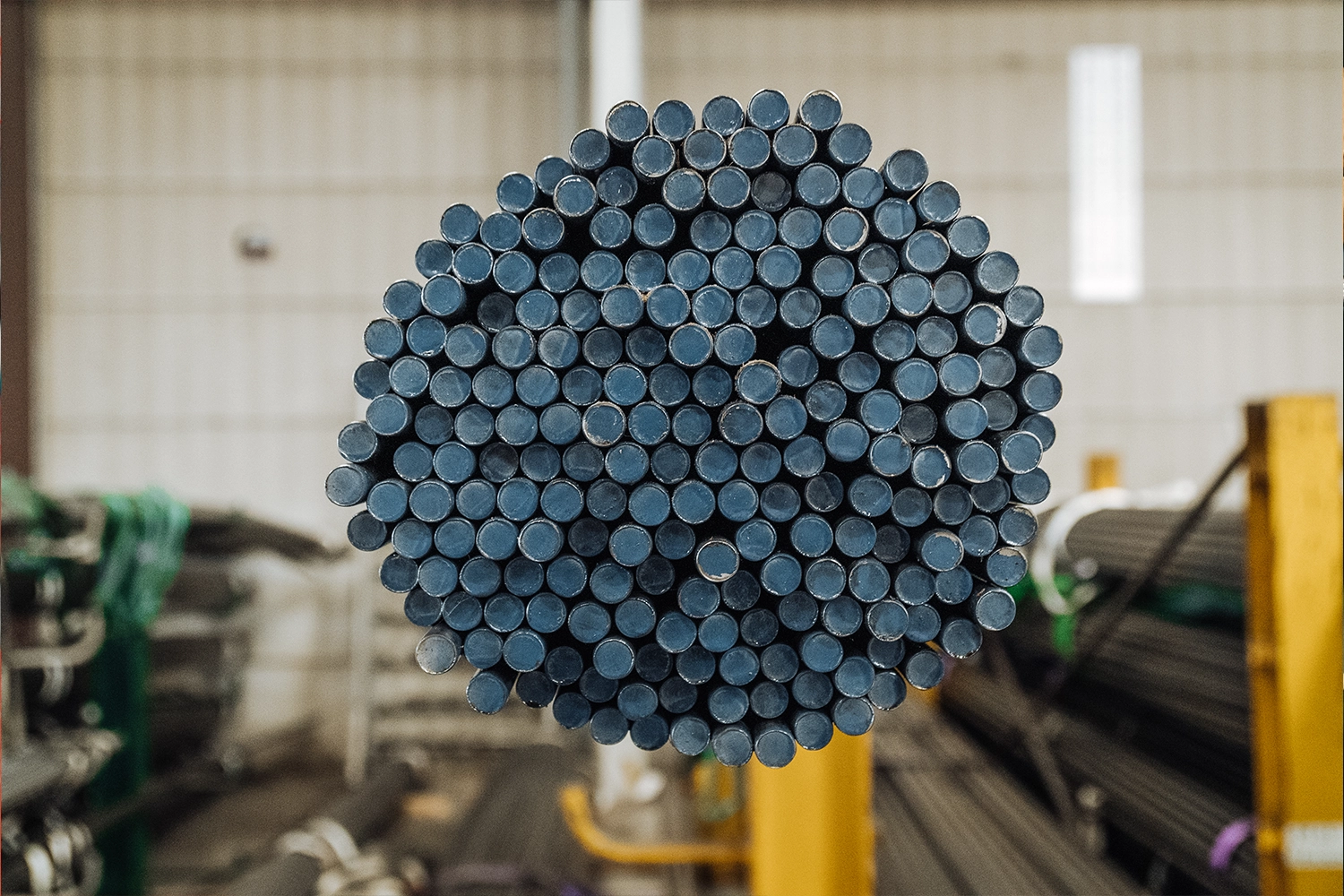

To ensure optimal deformation, we use drawn steel in grades 4.8 (S235), 5.8 (S355) and sometimes 8.8 (42CrMoS4), depending on the application. For stainless steel threaded products, we work with AISI 304 and AISI 316, both known for their excellent corrosion resistance. In addition, we can also produce in other materials, such as aluminum, titanium and various alloys.

| Screw thread | Flank diameter | Weight/M |

|---|---|---|

| M 6 x 1 | 5,25 | 0,17 |

| M 8 x 1,25 | 7,10 | 0,33 |

| M 10 x 1,5 | 8,90 | 0,50 |

| M 12 x 1,75 | 10,75 | 0,75 |

| M 14 x 2 | 12,60 | 1,00 |

| M 16 x 2 | 14,60 | 1,32 |

| M 18 x 2.5 | 16,25 | 1,65 |

| M 20 X 2.5 | 18,25 | 2.10 |

| M 22 x 2.5 | 20,25 | 2,55 |

| M 24 x 3 | 21,90 | 3,00 |

| M 27 x 3 | 24,90 | 3,80 |

| M 30 x 3,5 | 27,60 | 4,80 |

| M 33 x 3,5 | 30,60 | 5,75 |

| M 36 x 4 | 33,25 | 6,70 |

| M 39 x 4 | 36,25 | 8,10 |

| M 42 x 4.5 | 38,90 | 9,40 |

| M 45 x 4,5 | 41,90 | 10,80 |

| M 48 x 5 | 44,60 | 12,40 |

| M 52 x5 | 48,60 | 14,70 |

| M 56 x 5,5 | 52,25 | 16,80 |

| M 60 x 5,5 | 56,25 | 19,50 |

| M 64 x 6 | 59,90 | 22,10 |

Rolled screw thread is of much higher quality than cut screw thread. Because the material is pressed into shape instead of cut away, the structure remains intact and a smoother surface is created. This reduces friction, prevents wear and extends service life. This makes rolled thread the best choice for applications where strength and reliability are essential.

Merofix processes are aligned with DIN 3570, the international standard for U-brackets. Whether it concerns standard products or customization: at Merofix you are assured of consistent quality.

At Merofix, materials can receive different surface treatments:

| Diameter | Tensile strength | Min. yield strength | Min. stretch |

|---|---|---|---|

| 5 to 10 | 470 to 770 | 355 | 8 |

| 10 to 16 | 470 to 770 | 300 | 9 |

| 16 to 25 | 440 to 690 | 285 | 10 |

| 25 to 40 | 420 to 690 | 260 | 11 |

| 40 to 63 | 380 to 630 | 235 | 12 |

| Diameter | Tensile strength | Min. yield strength | Min. stretch |

|---|---|---|---|

| 5 to 10 | 650 to 950 | 520 | 6 |

| 10 to 16 | 600 to 850 | 450 | 7 |

| 16 to 25 | 550 to 800 | 400 | 8 |

| 25 to 40 | 530 to 780 | 350 | 9 |

| 40 to 63 | 520 to 770 | 350 | 10 |